Heat sinks for electronic components - Proven technology from Alutronic

Heat dissipation from electronic components is one of the basic problems faced by designers and installers of various devices, both consumer and industrial. Regardless of whether the issue concerns power converters, present in practically every piece of equipment, or processors, microcontrollers, etc., the development of heat sinks, the simplest, yet key element responsible for the thermal regulation of electronic components, depends on the technological development.

Most commonly, it acts as a heat exchanger, increasing the radiation surface area and thus allowing more efficient heat dissipation to the environment.

Alutronic is a heat sink manufacturer with nearly 50 years of experience. Through research, close cooperation with customers, and the search for the best materials – this German supplier is at the forefront of its industry today, offering a range of specialized solutions.

TME offers a wide range of heatsinks from Alutronic.

That is why we would like you to take a closer look at these products and related issues.

Types and mounting of heat sinks

For integrated circuits, e.g. in a BGA housing, thermal conductive adhesives are a common mounting method to speed up heatsink installation and provide good mechanical strength.

If heat transfer paste is used instead of glue, the heat sink can be pressed down with a spring tensioner, similar to the ones used in personal computers.

In the case of components in TO packages (e.g. TO-220, TO-218, or TO-202) a wide choice of options is available.

The most common are transistors, linear regulators, audio amplifiers and high-power LEDs, and therefore components that require effective cooling.

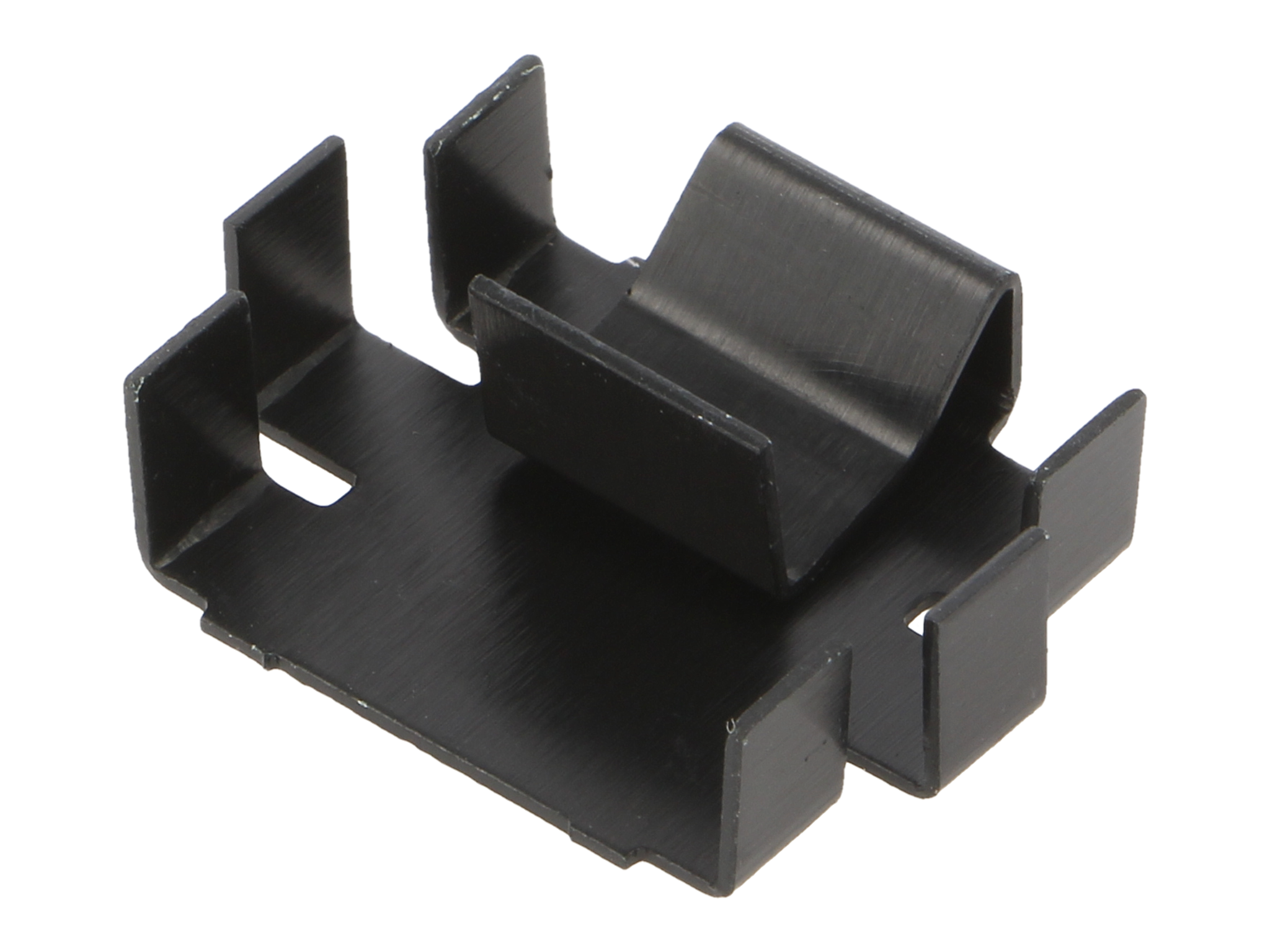

The cheapest and most popular solution is to use a clip-on heat sink, i.e. a "clip" adjacent to the metal part of the component (available as an accessory for other products).

If necessary, the heat sink may be equipped with additional cavities, grooves or ribs improving its effectiveness. Some models can be additionally soldered to the PCB for permanent connection.

FI344/SE

Anodized aluminium clip-on heat sink for TO220 housing.

Another type of heat sink used with the TO-220 and related enclosures is screwed to the housing. They are often much larger, adhere better to the system being cooled, and therefore dissipate heat more efficiently.

Thermally conductive pads are additionally placed between the two surfaces to support heat transfer. In addition, they electrically isolate the heat sink because the mounting screw is placed in a plastic sleeve so that it does not come into contact with the metal part of the element. Alutronic, through TME, offers a number of heat sinks designed in this way.

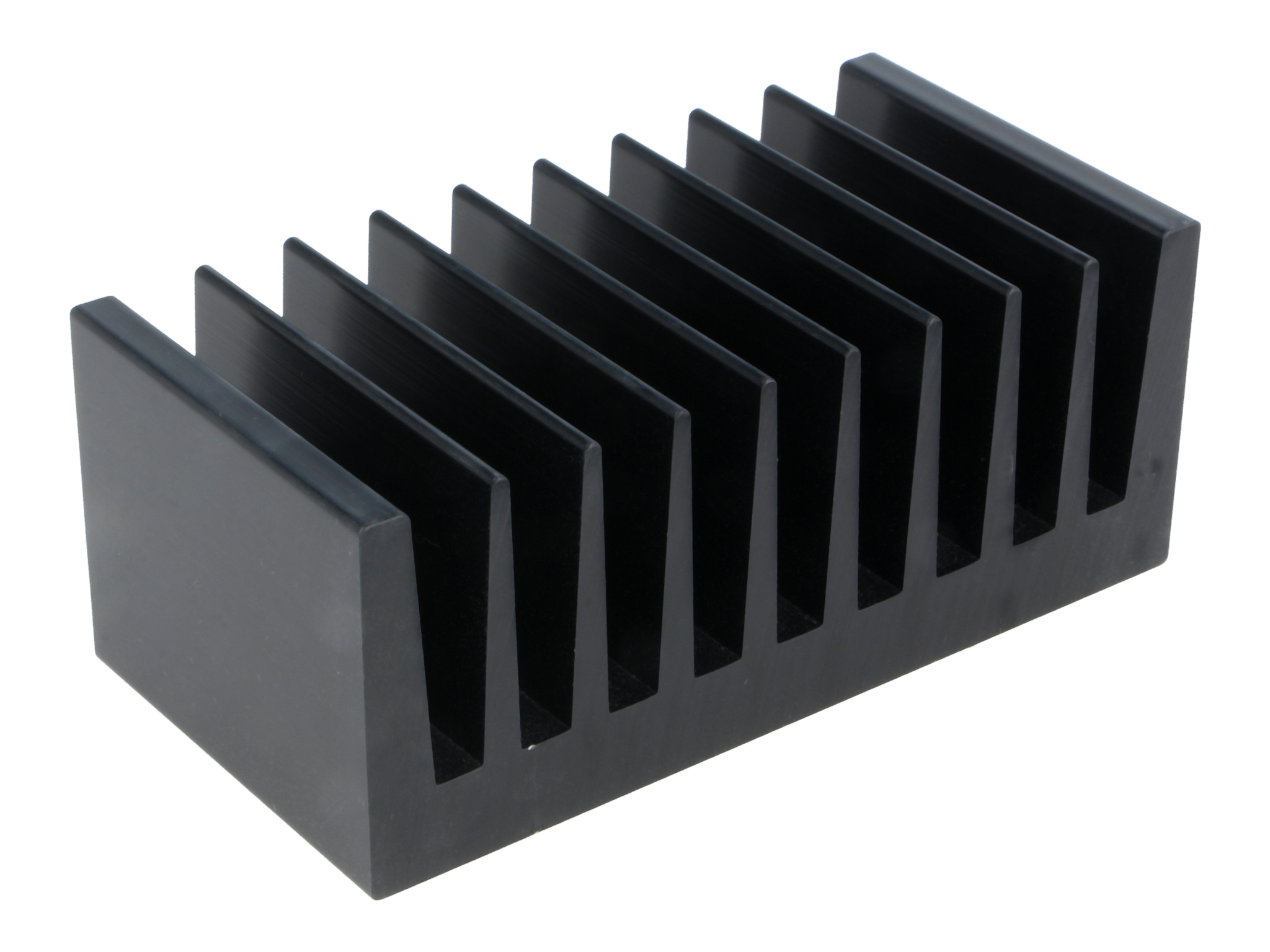

Custom heat sinks

Heat sinks are made from a variety of materials, although good heat conductors such as copper or aluminium, as in the case of Alutronic products, are most commonly used.

This material also has the advantage that it is lightweight, so it does not significantly increase the weight of the final product, which is important especially in the case of mobile applications. It can also be easily processed mechanically.

This means that in the case of a non-standard application, we can purchase universal heat sinks and easily adjust their dimensions to meet the needs of a specific project.

However, in many cases such machine (or even manual) processing is limited to tap a hole with a suitable thread in order to mount / hold heat sinks in place.

PR173/50/SE/UL

Extruded (finned) heatsink with low thermal resistance.

We encourage you to check out the full range of Alutronic products offered by TME.

The articles in our catalogue are available directly from our warehouses, which guarantees fast and direct shipment to the customer.

The original source of text: TME

.gif)